Equipment

Experience at Crafted Plastics Inc. has grown as we've been serving the plastic extrusion needs of manufacturers worldwide since 1982. Whether it's a basic polycarbonate tube or a more complex plastic profile, our commitment is to produce plastic extrusions that meet your specific requirements. Below is a summarized list of the fundamental equipment we will use to service you.

EXTRUSION EQUIPMENT

EXTRUSION EQUIPMENT

- 3-Davis Standard 3 1/2" 24:1 L/D Thermatic® extruders

- 3 - Davis Standard 2-1/2" 24:1 L/D non-vented, air-cooled Thermatic® III extruders

- 3 - Davis Standard DS-25 2-1/2" 24:1 L/D non-vented, air cooled extruders

- 1 - Davis Standard DS-125 1-1/4" extruder for use with co-extrusion applications

- 2 - Davis Standard DS-150 1-1/2" extruder for co-extrusion and small applications

- 1 - 1" Al-Be Industries Model 100 H 24:1

- 2.0 PVS Vacuum Sizer for close tolerance sizing of flexible PVC and Urethane tubing

- Mechanical Discharge Conveyor for Automatic Counting, Bagging and Sealing

- 4 - Planetary "Burr-Free" Cutters for round tubing

- In - Line Single Punch Units for small profiles

- Automatic Coiler/Winder with tension control

- Auxiliary equipment including vacuum tanks, air racks, pullers, traveling saws, cutters, and chillers

- 4" MT Precision vacuum tank w/PAVC Control

- On-Line Controls Measurement and Control System: in-line tubing Wall/OD/ID measurements. Feedback control and SPC capabilities

- 1 - Vacuum calibration table used for hollow profiles

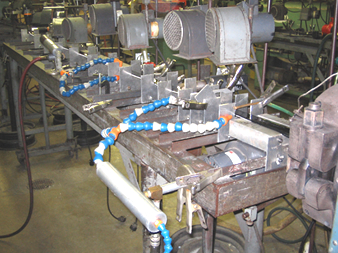

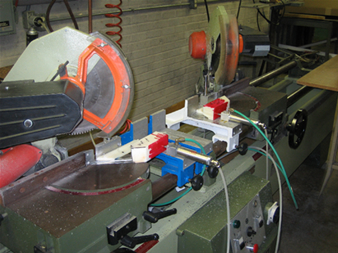

VALUE ADDED FABRICATION EQUIPMENT

- 2 - IBP Saws (automatic cut-off saw), ± .010" length tolerance on 3/8" to 23 ½" lengths

- 2 - TR2A Double Miter Saws, 0° to 45° angles on end cuts with a ± .015" length tolerance

- 2 - CDT Vertical Notching Saw 45° notches in profiles

- Commander Head Drill, 1 to 29 holes can be drilled at 7/16" centers simultaneously

- Multi Head Drill, 1to 10 - holes can be drilled at 3 ¾" centers simultaneously

- 75 ton & 40 ton Break Press, eight foot overall punching capacity

- Hot Stamp, 1 to 3 stamps simultaneously

- 3 - Drill Presses, standard & pneumatic

- Bagging, weigh counting, and sealing

- 2 - Ink Jet Printers for in-line printing - Black Ink

- 1 - Ink Jet Printer for in-line printing - Yellow Ink

- 1 - Accupunch - Accurate cutting & punching profiles in-line.

- 3 - Punch Presses

- 2 - Routers, standard

- 3 - Air rams

- Auto stretch wrapper

QUALITY ASSURANCE AND INSPECTION

- On-line documented process control checks

- C.W. Brabender PL2100 Plasti-Corder

- Dial Calipers: 90", 40", 12", 6"

- NWA Quality Analyst Statistical Quality Software

- X-Rite QA Master + SP68 Spectrophotometer

- Caliper Certification and Gage R&R Software

- 14" Series Twenty Gage Master Optical Comparitor

- Brown & Sharpe Dial Indicator

- Depth Micrometer Gages

- Digital Ball Micrometer

- Certification Blocks

- Pi Tapes

- 26" Cal-X-Tender

- Max 2000 Moisture Analyzer

ENGINEERING/TOOLING CAPABILITIES

- Charmilles Robofil 290 Wire EDM Machine

- Charmilles HD 20 EDM Hole Drill

- HURCO VM1 CNC Mill with 26" x 14" X18" work area

- Espirit - CAD Software

- MasterCam - CAD Software

- Bridgeport (Vertical) Mill

- Acer (Hydraulic) Surface Grinder

- Turnmaster Lathe

- Arc Radial Drilling Machine

- Jet Bandsaw - " Cut Off"

- Grob Bandsaw - "Vertical"

- Gesswein Die Polisher

- Temperature & humidity controlled tool room.